Share this

What Is Economic Order Quantity and How to Calculate It

by Rin Mosher on Apr. 12, 2024

Inventory is one of the most important elements of any business. Finding the balance between having enough inventory to meet demand without overspending on excess stock is a constant challenge for businesses of all sizes. The concept of Economic Order Quantity (EOQ) helps tackle this challenge.

This proactive approach to inventory management uses mathematical calculations and data analysis to determine the optimal order quantity that will minimize costs while meeting demand. Keep reading to learn what economic order quantity is, how it works, how to find EOQ, and when using the EOQ formula can benefit your business' supply chain strategy.

What Is Economic Order Quantity (EOQ)?

Economic Order Quantity (EOQ) is a mathematical model used to determine the ideal amount of inventory you should order or produce at one time. It helps logistics managers minimize logistics costs and space usage and mitigate the risk of stockouts by considering variables such as demand, ordering, holding, and production or purchase costs. Calculating EOQ can give you a reliable basis upon which to make ongoing purchasing decisions.

How Economic Order Quantity Works

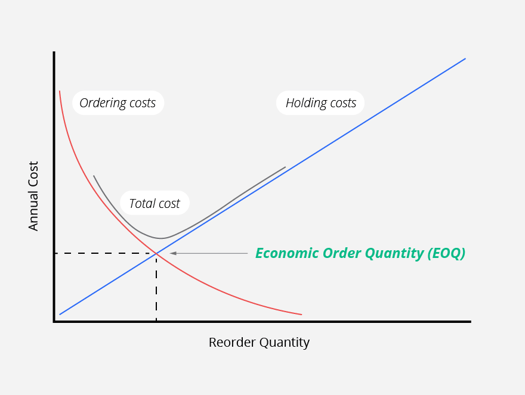

EOQ is based on the premise that there is a trade-off between the costs associated with holding excess inventory, known as holding or carrying costs, and the costs incurred from replenishing inventory, referred to as ordering costs. The economic order quantity model helps find the balance between the two.

Holding costs include the variable costs associated with keeping inventory in a warehouse for an extended period of time, such as storage, management, and insurance. These are all necessary expenses if you want to have products in stock and ready to be fulfilled every time an order is placed. However, at a certain point, holding a large quantity of inventory can become cost-prohibitive, where more is spent to store it than the potential profits that could be made by selling it.

Ordering costs encompass all the expenses that come with ordering inventory, like administrative and transportation fees. These costs are generally fixed but can decrease with increased order quantity. Shipping carriers that base their pricing on economies of scale, for instance, charge less per individual package if you order more.

In any case, there is a distinct inverse relationship between holding costs and ordering costs. Where one goes up, the other will likely go down, and vice versa. Economic order quantity defines the exact point at which these two lines intersect for maximum savings.

Economic Order Quantity vs. Minimum Order Quantity (MOQ)

While both Economic Order Quantity and Minimum Order Quantity (MOQ) are used to manage inventory levels, there are key differences between the two concepts.

Minimum Order Quantity is defined by suppliers as the least amount of a product a business must purchase in a single order. It is individually set by vendors/suppliers and based on their production capabilities and costs. This means that the MOQ for a certain product can vary from supplier to supplier.

EOQ, on the other hand, calculates the quantity of inventory that should be ordered at one time to minimize business spend. Unlike MOQ, which is supplier-driven, EOQ is determined by the buyer based on their demand, costs, and operational requirements. It aims to find a balance where the combined costs of ordering and holding inventory are at their lowest.

In scenarios where the EOQ calculation is less than the MOQ, businesses may need to negotiate with suppliers or adjust their inventory strategies to accommodate the difference. This could result in potentially holding more inventory than the EOQ suggests as optimal. Conversely, if the EOQ is higher than the MOQ, the business can order at its EOQ without concern for not meeting the MOQ requirements.

Why Is EOQ Used?

Above all else, logistics managers use economic order quantity to optimize and save on inventory costs. EOQ and other tools like the reorder point formula shed light on exactly when new orders should be placed so as to mitigate the pitfalls of overstocking.

While having lots of inventory on hand might seem like a good thing - because it means you always have products to fulfill orders with - too much can tack on unnecessary storage and maintenance costs. If a business chronically overstocks inventory, it will inevitably spend more than necessary while simultaneously risking product damage and/or spoilage. Every unit costs money at the end of the day, so with a higher quantity comes a greater commitment to long-term storage and associated cost expenditure.

Overspending on inventory can also lead to opportunity costs. If a business has its money tied up in excess inventory, it may not have the necessary capital for other investments or opportunities that could potentially drive growth and profitability.

On the other hand, having too little inventory available can result in stockouts and backorders, leading to dissatisfied customers and lost sales. This can not only affect the company's revenue but also its reputation.

How to Find Economic Order Quantity

In order to calculate economic order quantity, you will need to know your holding costs, setup costs, and customer demand rate.

1. Determine Holding Costs

Holding cost, as explained earlier, encompasses the expenses associated with holding inventory. These can include storage costs, insurance, and taxes.

2. Identify Your Ordering Cost

Ordering or setup order cost refers to the fixed expenses involved in placing an order for new inventory, such as labor, transportation fees, and administrative overhead.

3. Define Your Demand Rate

Demand rate is the amount of product that your customers demand over a certain period of time. The most straightforward method to define your annual demand rate, which can be measured in units or dollars, is by analyzing historical sales data. Look at the quantity of each product sold over a given period, such as a month or a year, to directly measure demand based on actual sales performance.

4. Calculate Economic Order Quantity

The EOQ formula is expressed below.

EOQ = √(2DS/H)

Where:

D = Annual demand in units

S = Ordering cost per order

H = Holding cost per unit

Example Economic Order Quantity Calculation

Let's say your annual demand for a product is 1000 units, your ordering cost per order is $50, and your holding cost per unit is $5.

EOQ = √(2*1000*50/5) = 200 units

This means that ordering 200 units at a time would minimize your total inventory cost.

The economic order quantity formula is widely helpful, but other inventory management strategies can be equally useful. Use our inventory management calculator for quick answers on where your total inventory cost, ending inventory level, inventory turnover, and reorder point should be.

Download Our Free Inventory Management Calculator

What to Know Before Using Economic Order Quantity

Economic order quantity appears to be a catchall solution to the challenges ecommerce businesses usually face when determining optimal reorder levels and reorder quantities. However, it's important to realize that this method of inventory management has limitations. In fact, there are times when using it can produce skewed numbers that misguide decision-making.

Here are a few things worth knowing before employing EOQ in your own ecommerce order fulfillment strategy:

EOQ Assumes Consistent Demand

The biggest issue of economic order quantity is that it assumes demand will always stay the same. Ecommerce businesses know that to be false, as order volume can be influenced by everything from marketing campaigns to seasonality. Those who experience frequent fluctuations in demand will benefit less from EOQ unless they recalculate it on a periodic basis. Otherwise, the final number won't reflect changes to order costs and carrying costs.

EOQ Works Best With Fixed Costs

Based on a principle similar to changes in demand, the accuracy of economic order quantity calculations can vary with fluctuating costs. The expenses that go into determining EOQ – including ordering costs like processing and shipping, and carrying costs such as storage fees – can change without warning. This is especially relevant for small businesses that may not have fixed contracts with supply chain partners or warehouse providers. In these cases, EOQ may not be as effective in optimizing inventory cost levels.

EOQ Doesn't Account for Lead Time

Another factor that can throw off EOQ calculations is lead time. Variations in lead time are known to cause inventory shortages and overstocking, which can disrupt the ideal ordering pattern suggested by EOQ. This is because the economic order quantity formula only takes into account current inventory levels and demand without considering how long it takes for new stock to arrive. Businesses with longer lead times may need to adjust their EOQ accordingly or find alternative methods of managing their inventory.

EOQ Doesn't Take External Variables Into Account

The viability of economic order quantity relies on a business' ability to manage unexpected changes in inventory levels. Doing so is challenging from a theoretical standpoint, and when factoring in uncontrollable variables, it becomes even more difficult. Supply chain blockages, shrinkage, and spoilage are just a few examples of external factors that can impact inventory levels and disrupt the ideal ordering pattern suggested by EOQ. All need to be considered alongside EOQ calculations to ensure efficient inventory management.

Optimize Your Economic Order Quantity with Shipfusion

If there's one thing to take away from the concept of economic order quantity, it's that a little planning can go a long way in terms of fulfillment efficiency and cost-effectiveness. The challenge lies in properly and consistently calculating changes in expenses and demand as they happen, and adapting your inventory management strategy accordingly.

A third-party logistics (3PL) partner like Shipfusion can take the burden of optimizing inventory levels off your shoulders with the help of advanced software and experienced fulfillment experts. Our solutions are designed to streamline your operations, reduce costs, and improve customer satisfaction. So why wait? Reach out to us today to learn more about how we can help your business scale while keeping costs down.

Share this

You May Also Like

These Related Articles

Deal With Slow-Moving Inventory Like A Pro!

Minimum Order Quantity (MOQ) In Ecommerce Explained

Understanding What Merchandise Inventory Includes

- October 2025 (1)

- September 2025 (6)

- August 2025 (8)

- July 2025 (16)

- June 2025 (22)

- May 2025 (27)

- April 2025 (27)

- March 2025 (26)

- February 2025 (26)

- January 2025 (34)

- December 2024 (16)

- November 2024 (22)

- October 2024 (22)

- September 2024 (27)

- August 2024 (9)

- July 2024 (8)

- June 2024 (5)

- May 2024 (8)

- April 2024 (7)

- March 2024 (6)

- February 2024 (6)

- January 2024 (5)

- December 2023 (3)

- November 2023 (3)

- October 2023 (5)

- September 2023 (4)

- August 2023 (2)

- July 2023 (1)

- June 2023 (4)

- March 2023 (2)

- October 2022 (1)

- September 2022 (5)

- August 2022 (4)

- July 2022 (7)

- June 2022 (4)

- May 2022 (4)

- April 2022 (6)

- March 2022 (2)

- February 2022 (1)

- January 2022 (3)

- December 2021 (2)

- November 2021 (4)

- October 2021 (2)

- September 2021 (5)

- August 2021 (4)

- July 2021 (4)

- June 2021 (3)

- May 2021 (2)

- April 2021 (3)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (4)

- November 2020 (2)

- October 2020 (4)

- September 2020 (2)

- July 2020 (5)

- June 2020 (4)

- May 2020 (2)

- April 2020 (2)

- March 2020 (4)

- February 2020 (1)

- December 2019 (1)

- May 2018 (1)

- March 2018 (2)

- February 2018 (3)

- January 2018 (3)

- November 2017 (3)

- July 2017 (4)

- March 2017 (3)

- February 2017 (5)

- January 2017 (3)

- December 2016 (4)

- November 2016 (6)

- October 2016 (6)

- October 2015 (1)

- September 2015 (1)

- June 2015 (3)

- May 2015 (3)

- August 2014 (1)

- July 2014 (1)

- March 2014 (1)

- February 2014 (1)

.png?width=3334&height=468&name=Shipfusion_Logo%20Color%20Light%20(1).png)

.png?width=2850&height=400&name=Shipfusion_Logo%20Color%20Light%20(1).png)